GyroMaster™

Significantly quicker and much more accurate, the north-seeking GyroMaster™ is the future of the downhole industry and is rapidly taking over the sector.

the new definition of accuracy

GyroMaster™

The north seeker reigns king of downhole gyro survey tools. Unaffected by magnetism and consistently more accurate than the reference gyro, it allows the user to pinpoint targets with absolute values, rather than referencing manual inputs.

SPT’s truly continuous mode allows users to obtain data points at every centimeter and at all inclination ranges from completely vertical or horizontal. North seeking gyros that use SPT’s Navibore™ technology are able to eliminate all drift, thanks to an automated QC function that produces completely accurate data.

The north-seeking GyroMaster has given a new definition to accuracy.

How to confirm the accuracy of your downhole survey tool

With the amount of investment that goes into a mining project, transparency of tools should be a standard in the industry. Here are a few ways that you can confirm your tool is as promised:

Perform an in-run/out-run survey

This means completing 2 independent surveys of the borehole to ensure that the data matches. This is a standard procedure and QC measure incorporated into Navibore™ technology

Land surveyor verification

Having an external surveyor complete a triangulation to confirm accuracy

Ask your manufacturer

They should be required to show tha ability to measure vertically -89°, in continuous mode and compare that difference in-run (downward) and out-run (upward) measurements does not exceed 0.1% of measured depth in N-S/E-W coordinates

Test your tool

Your tool should be tested to the environmental conditions that it will be used in.

SPT has been a leader and authority on downhole accuracy for over 20 years.

Due to its operation being based on the angular velocity of the Earth and not on magnetism, the GyroMaster™ has multiple applications and its use is increasingly widespread in Geology and major mining exploration projects.

UNDERSTANDING THE TRUE ACCURACY OF A GYRO SURVEY TOOL

3 Sigmas for Standard Deviation

To understand the true accuracy of a gyro survey tool, SPT considers the best practice and what should be industry standard is to quote to 3 sigmas as it will give you a 99.7% assurance that the measured value will be what it is stated.

The key of SPT’s high precision is continuous survey mode, while most tools establish data points every 30 meters. SPT’s proprietary Navibore™ solid-state gyro technology registers data points at every centimeter to determine the exact position along the entire run.

Leader in the industry

Trajectory measurement of various tools

The following table gathers the data and technical specifications of different tools, taken from website of their respective manufacturers. Here the error in the final coordinates is evident. Drill trajectory measurement with the use of the GyroMaster™ True North seeking gyroscope reduces this error to a minimum.

GyroMaster™ –

North Seeking Solid State Gyro

GyroMaster™ is a north-seeking gyro with sold state sensors for all downhole applications. The only gyro in the mining industry that is capable of continuous surveying of azimuth from vertical to any orientation.

Unaffected by magnetic field

GyroMaster™ can be used in magnetic fields as it measures the projection of the angular velocity of the earth on its axis of rotation. Capable to register data points every cm for industry leading accuracy, and surveying at any inclination where you can automatically receive two highly accurate independent surveys from every run.

Highest standard of quality control – QA/QC

GyroMaster™ uses SPT’s proprietary Navibore™ technology, which can register data points at every centimeter for industry leading accuracy. Capable of surveying in any application, customers can automatically create highly accurate independent survey. Obtain data in real-time and automatically generates detailed pdf reports that verify collected data via separate independent surveys. Ability to manage and share survey data with SmartCloud™.

Pull core and complete survey at the same time

Improve your team´s efficiency by doing two tasks at once. With Core Retriever™ overshot assembly you can pull cores and survey simultaneously. Increase drilling productivity and deliver great results.

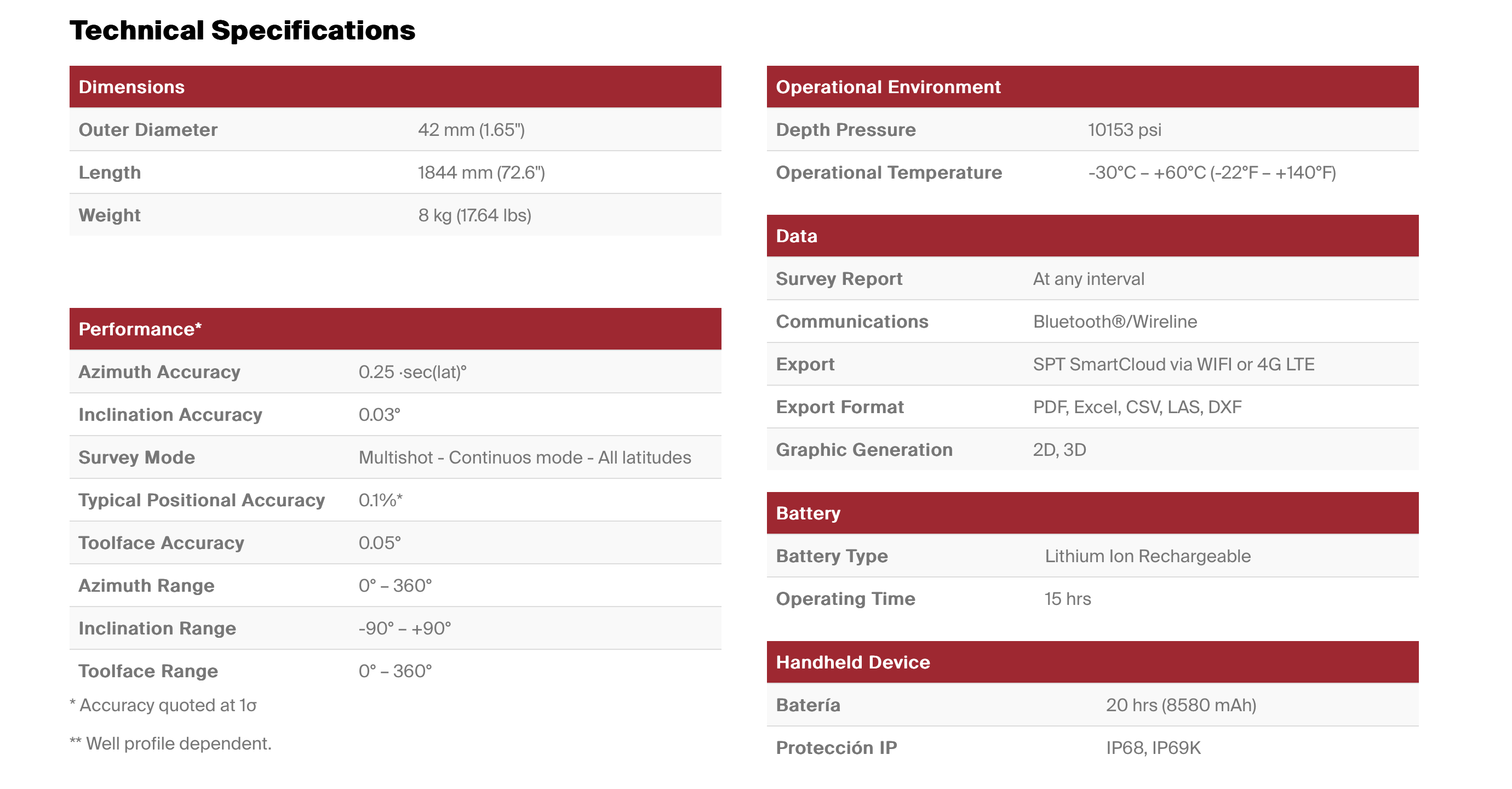

GyroMaster™

Technical Specifications

GyroMaster™ works with

Core Retriever™

Core puller and complete downhole survey in the same time

SPT SmartCloud™

Cloud platform for survey data sharing and management

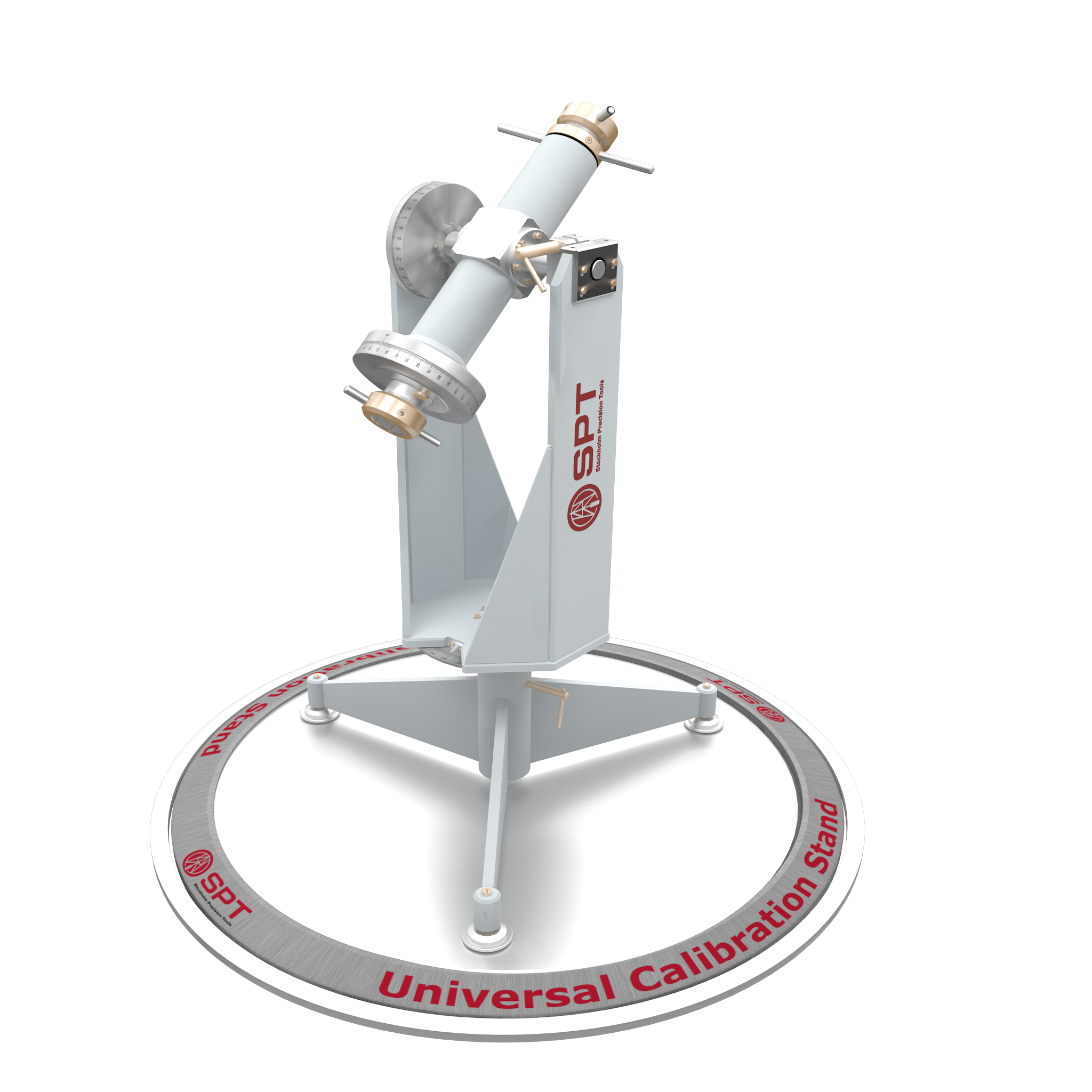

CalibraCheck

Portable calibration on-site to ensure your quality control